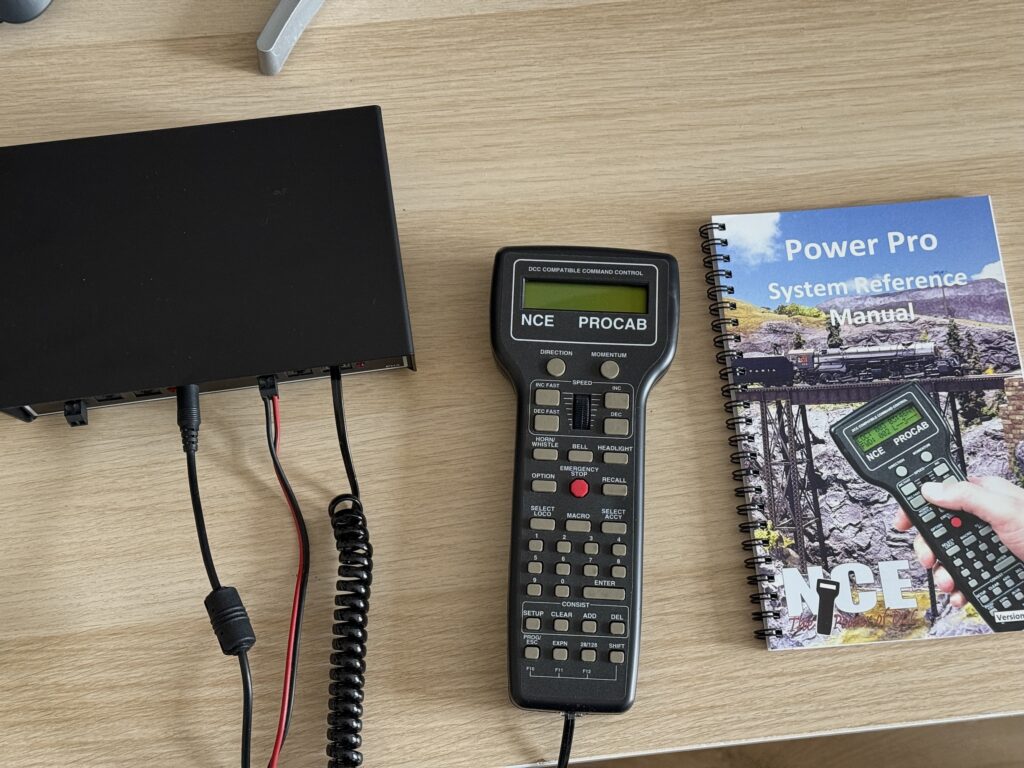

Wiring and Laying Tracks

Wiring and laying track on the SP Burbank Branch in N scale

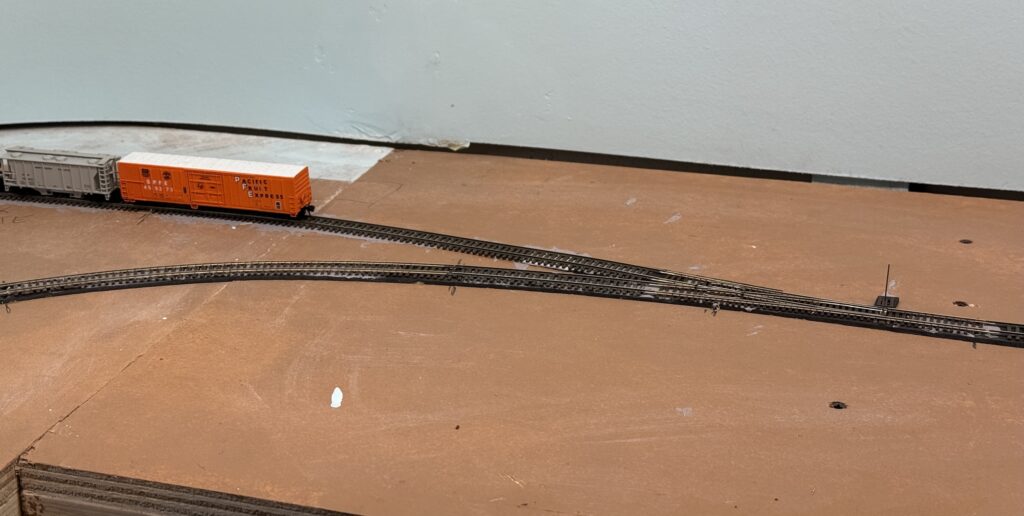

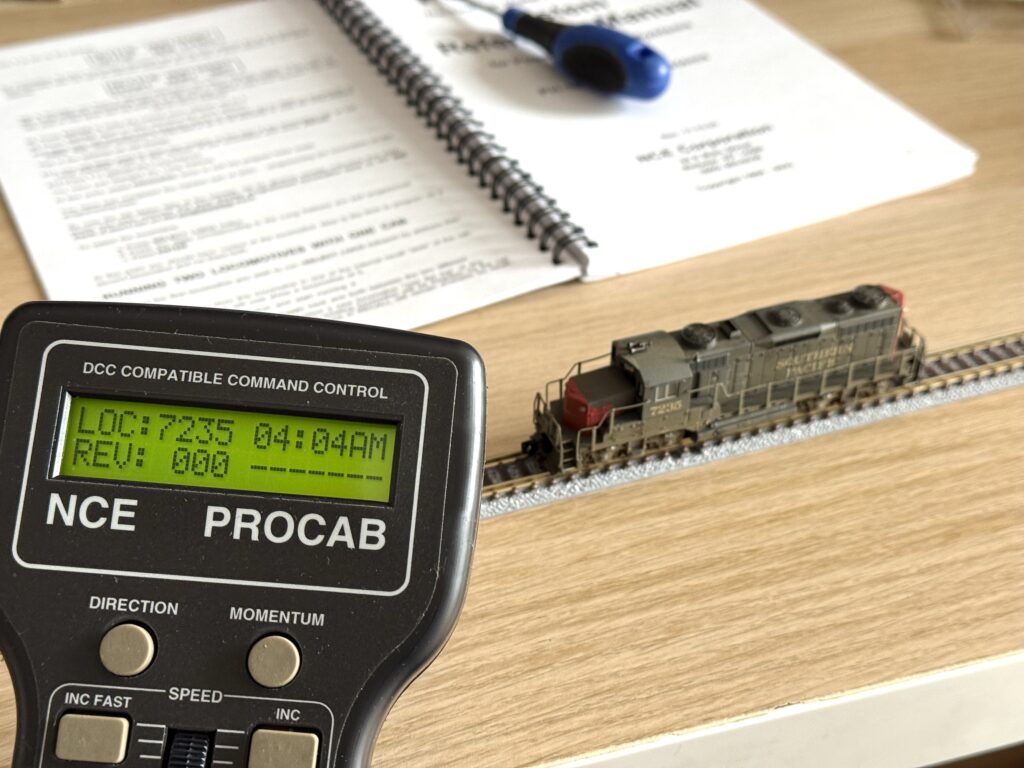

After completing wiring and laying tracks on the first section of my N scale switching layout, I continued extending the trackwork.

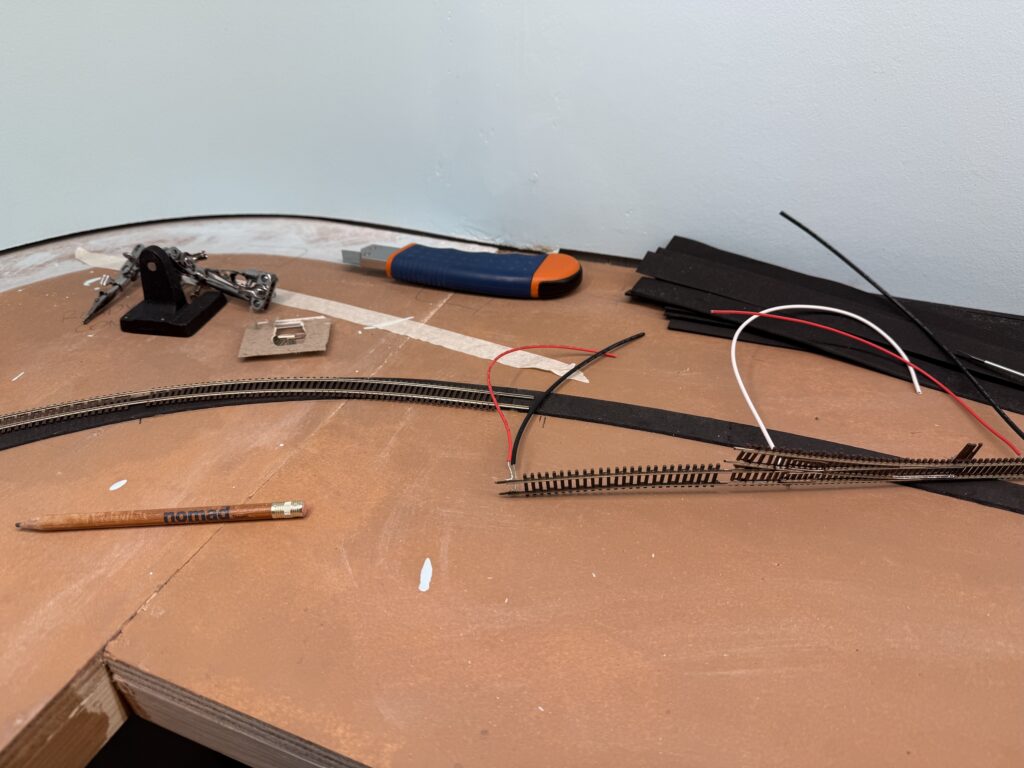

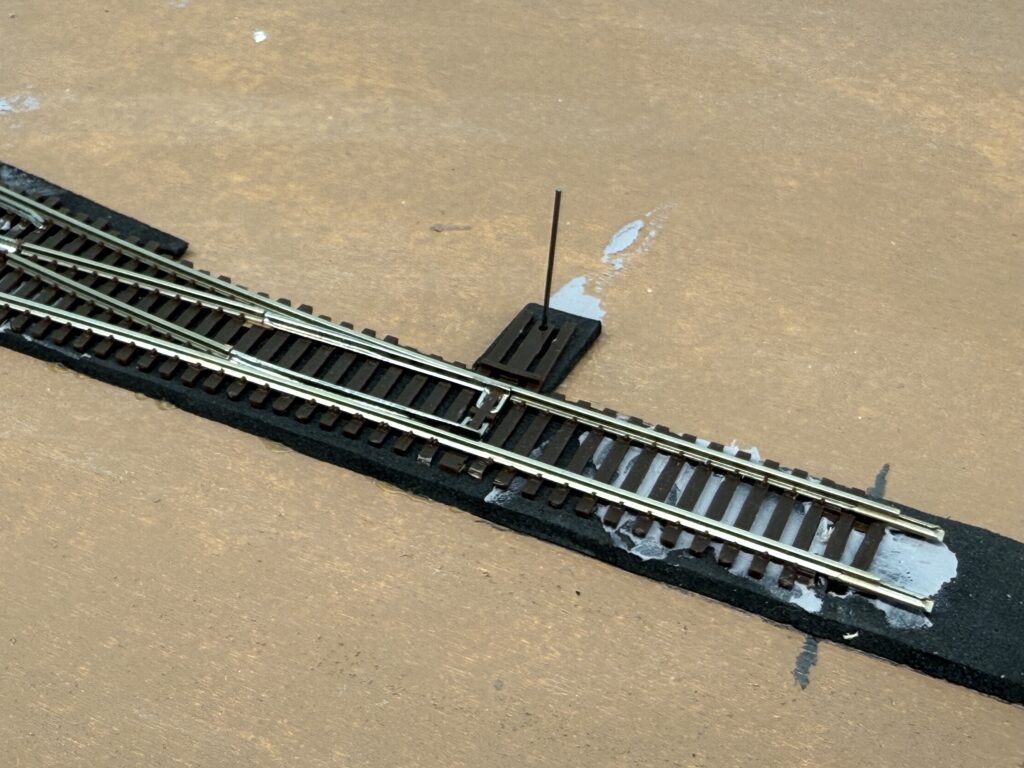

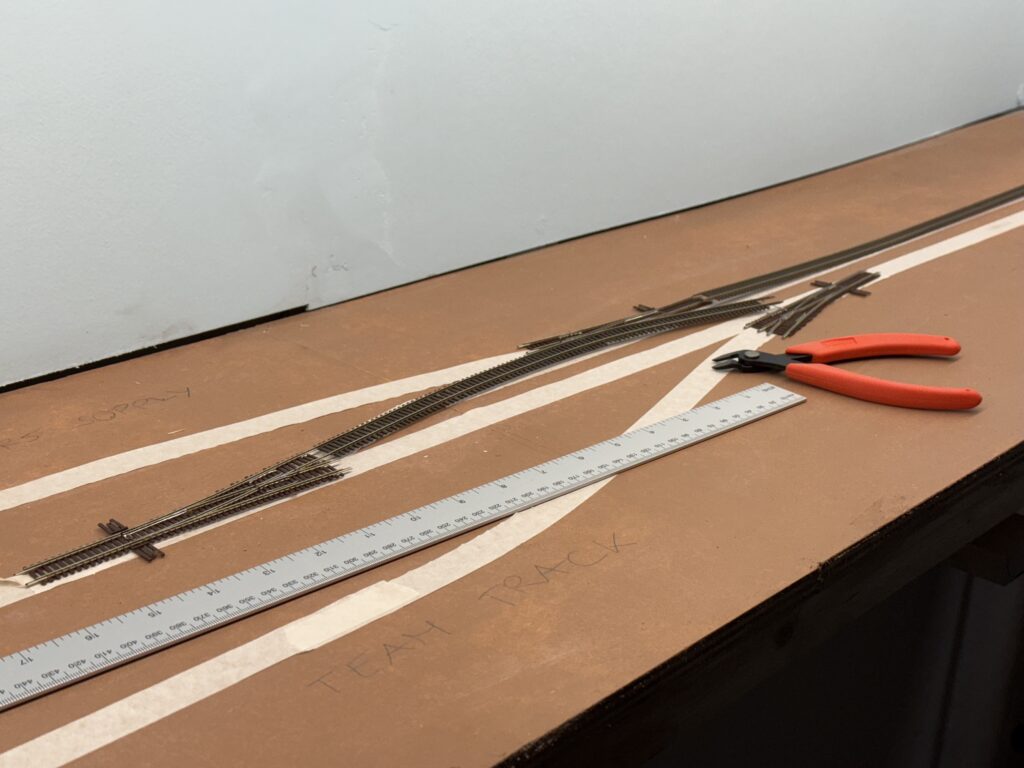

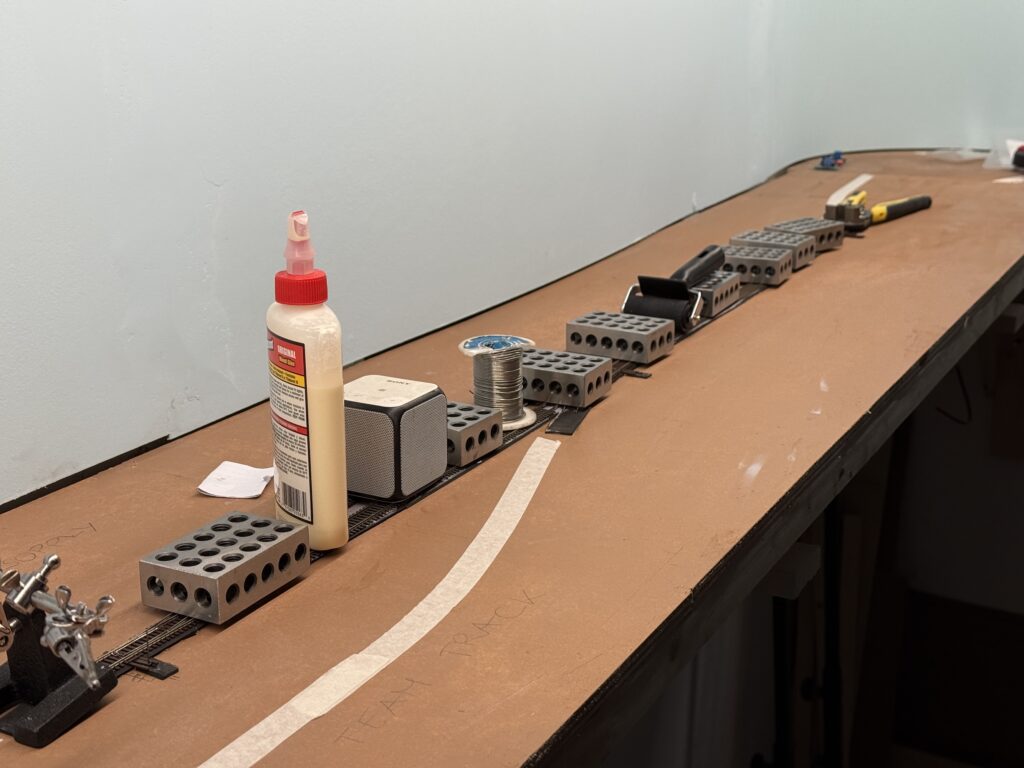

I started test-fitting Atlas Code 55 turnouts and Micro Engineering Code 55 flextrack. I had used this combination on a larger N scale SP layout, and it worked well.

Unlike previous projects, I bought a Xuron cutter this time – specifically the 2175B model, which also suits N scale track.

I used to cut rail with a Dremel and cutting disk, but the Xuron cutter feels much more comfortable.

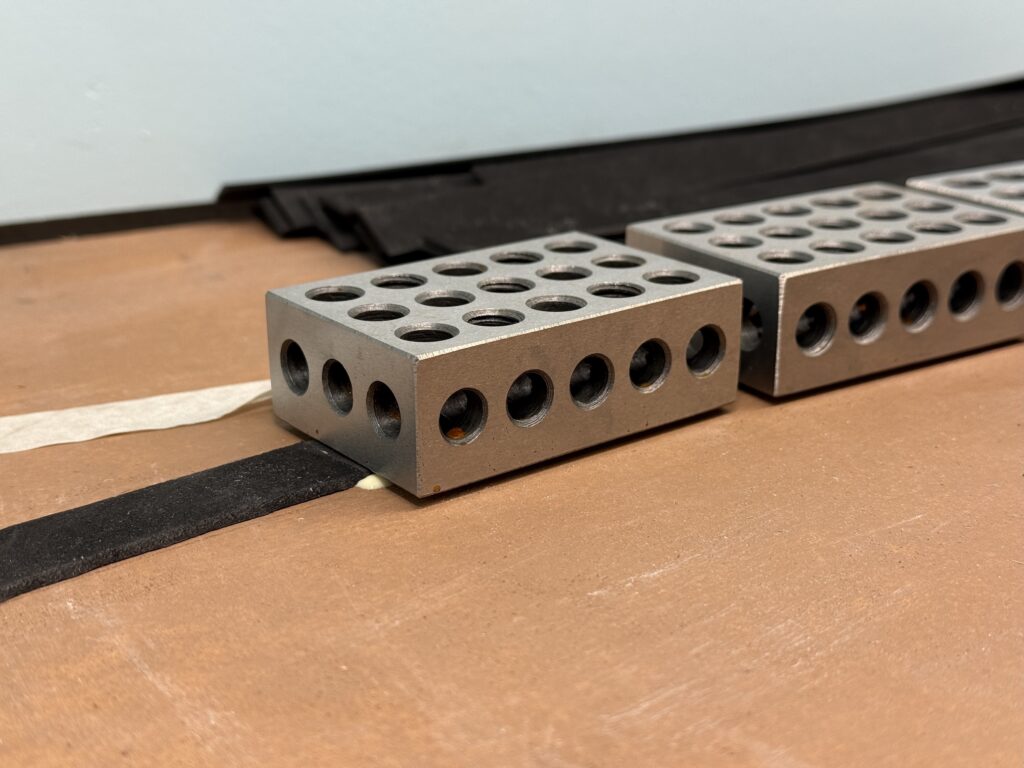

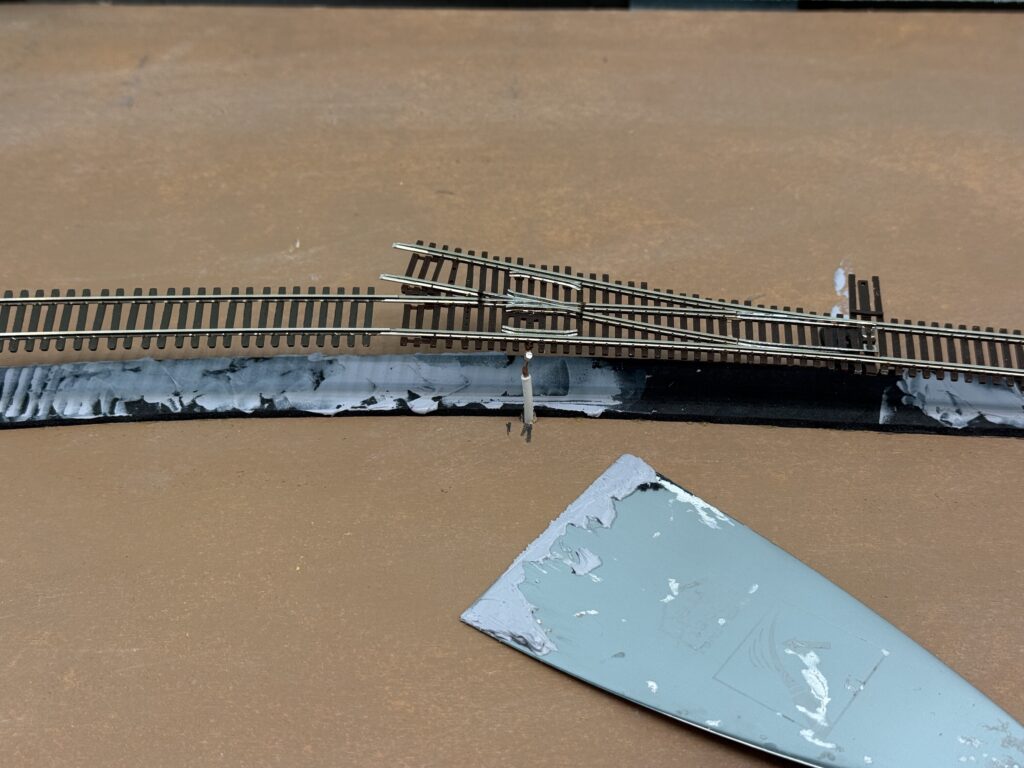

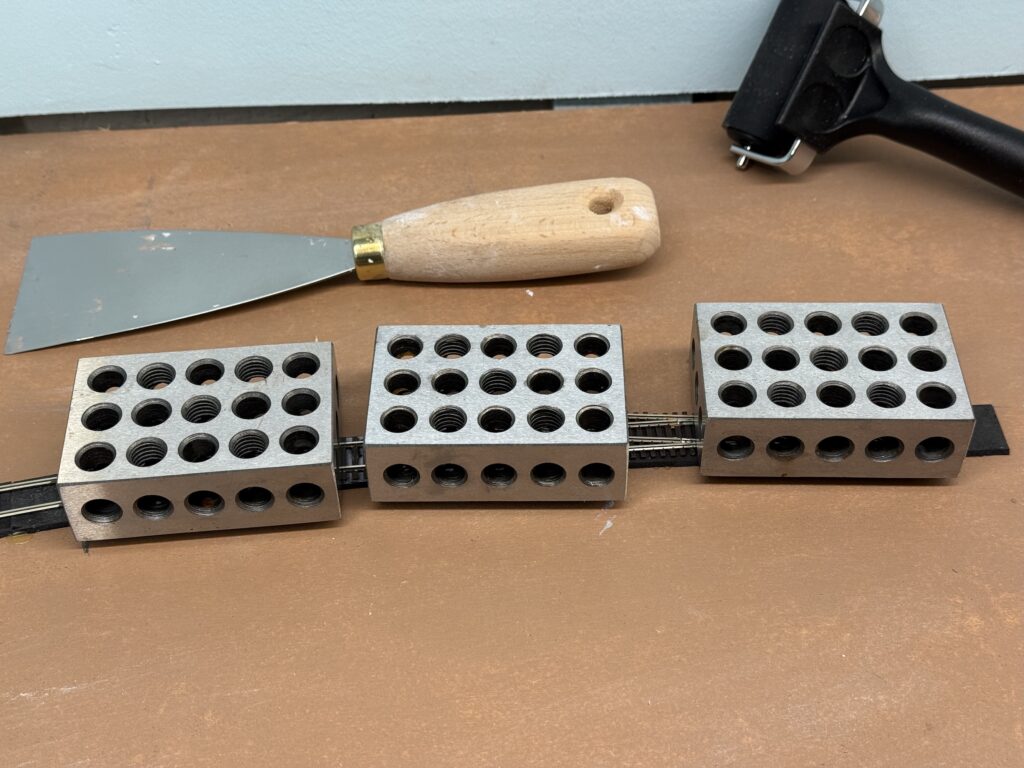

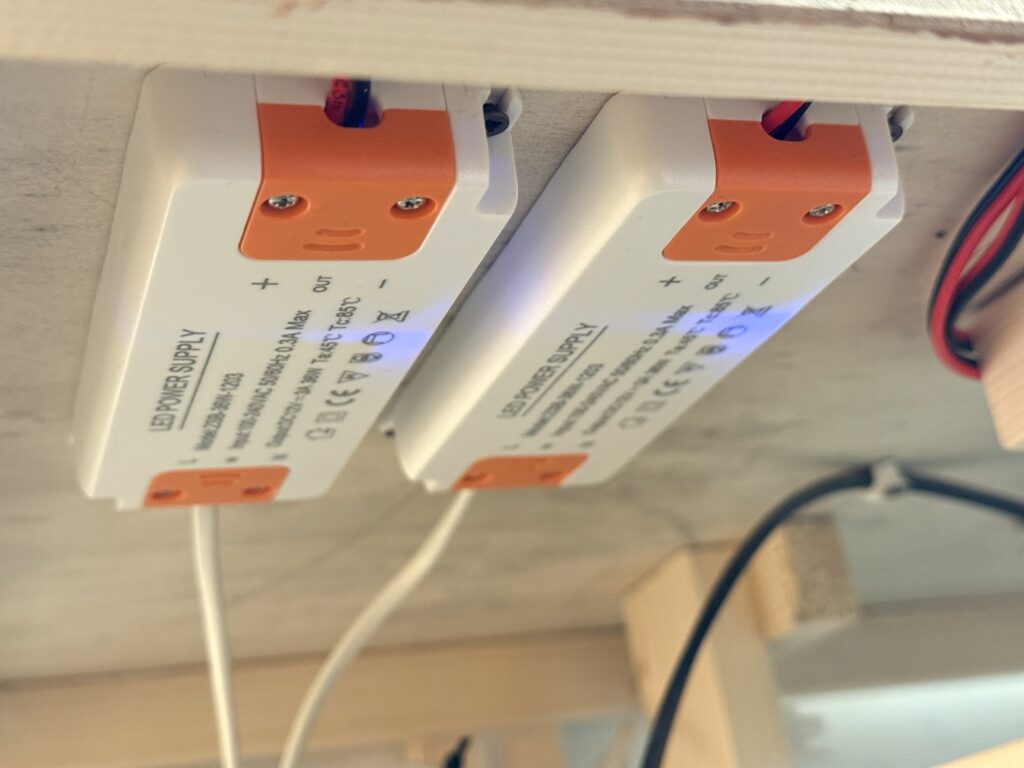

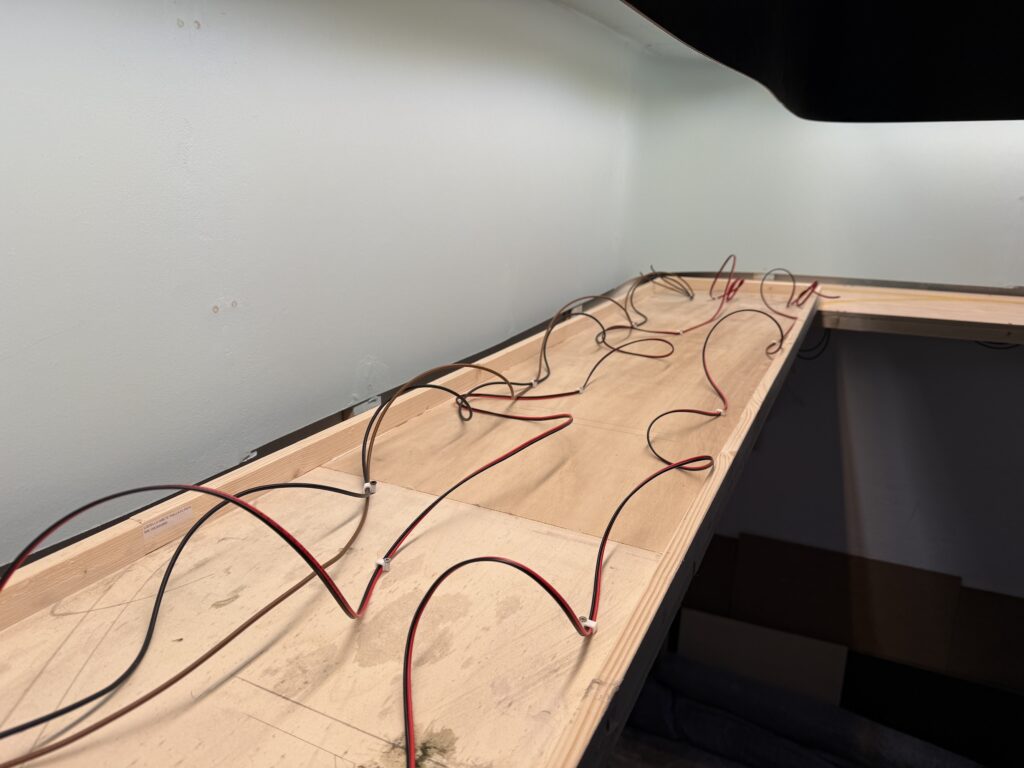

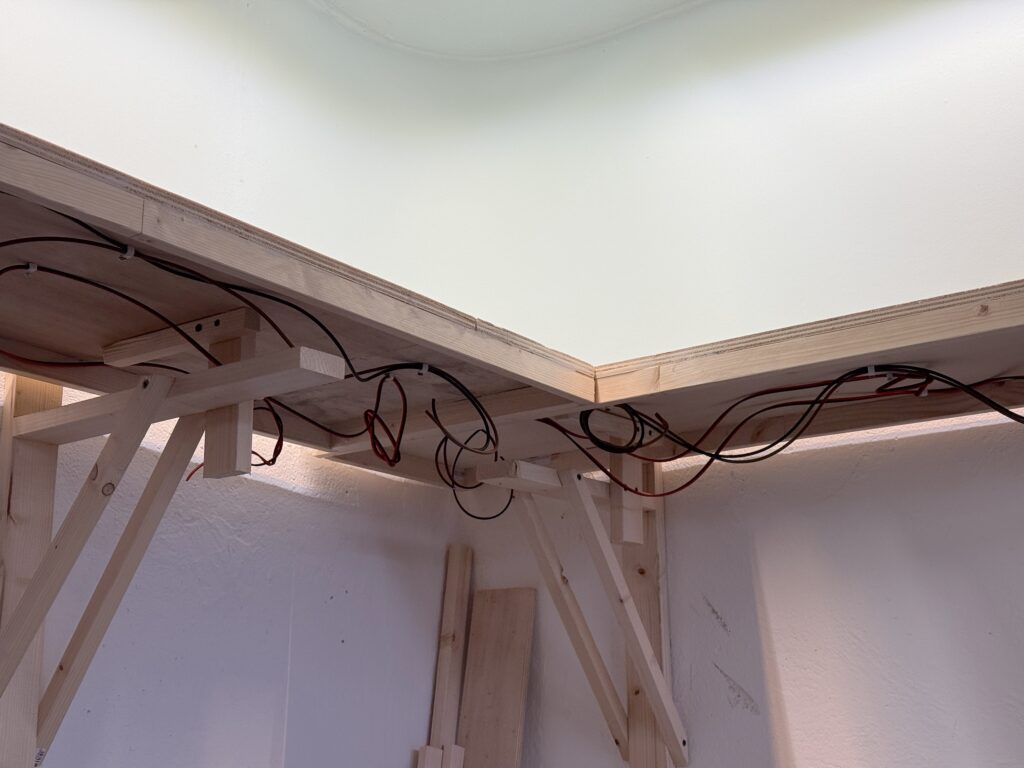

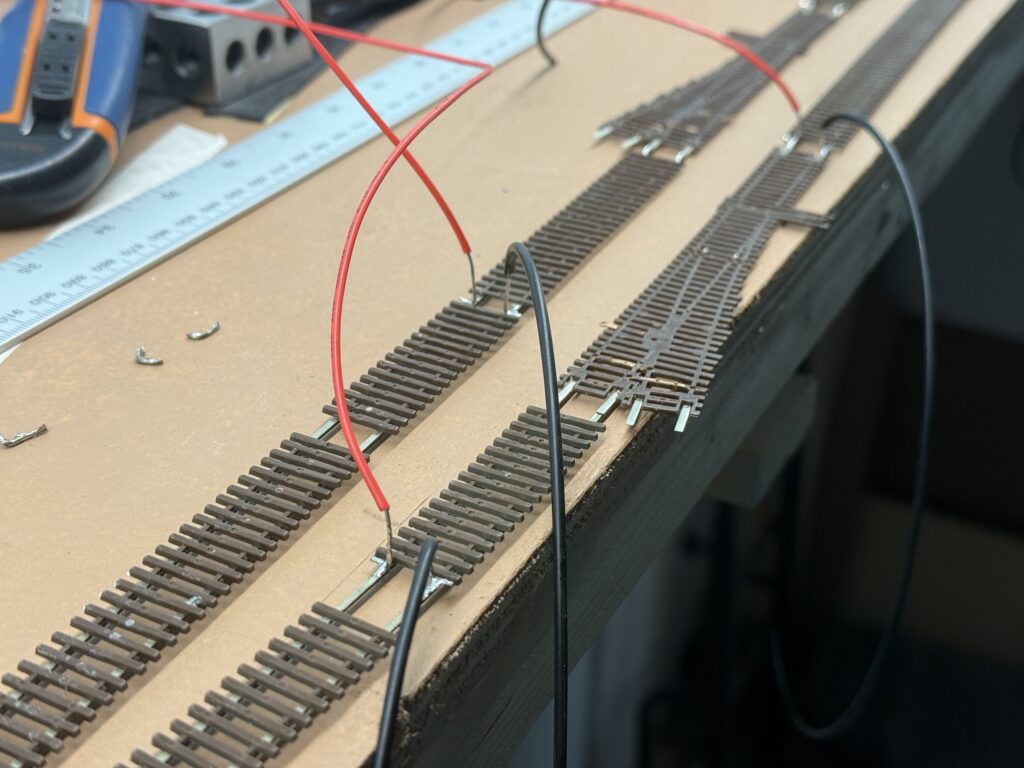

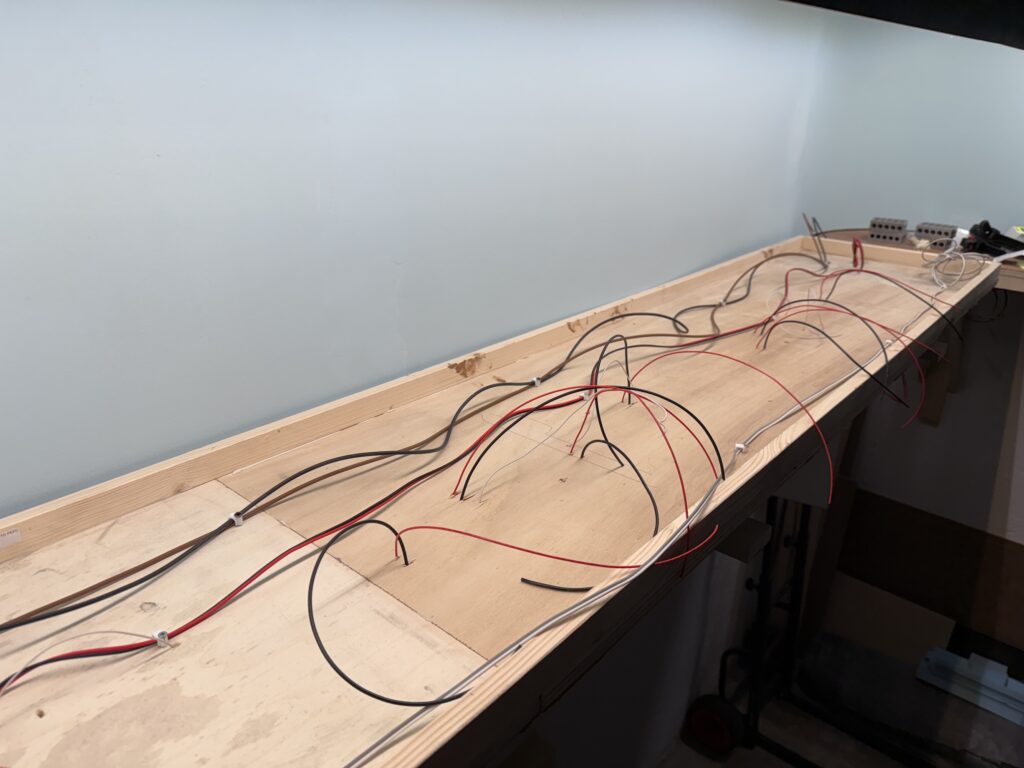

While waiting for the EVA foam roadbed glue to cure, I soldered feeders to the rails using a 15W soldering iron and rosin core flux.

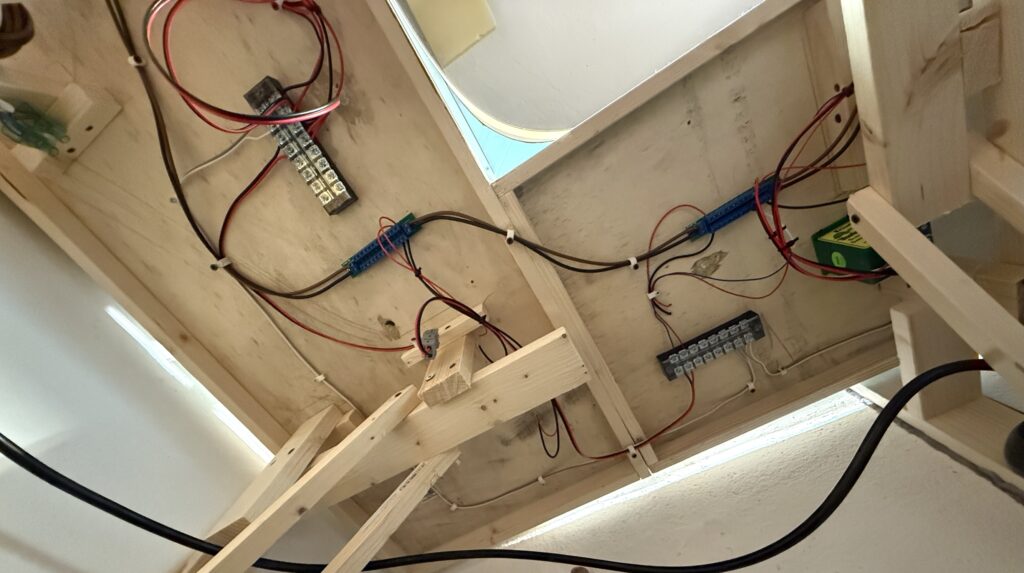

To make wiring easier, I flipped the base upside down. It isn’t screwed to the benchwork yet, so this was simple.

Next, I glued the track to the roadbed using a thin layer of acrylic caulk.

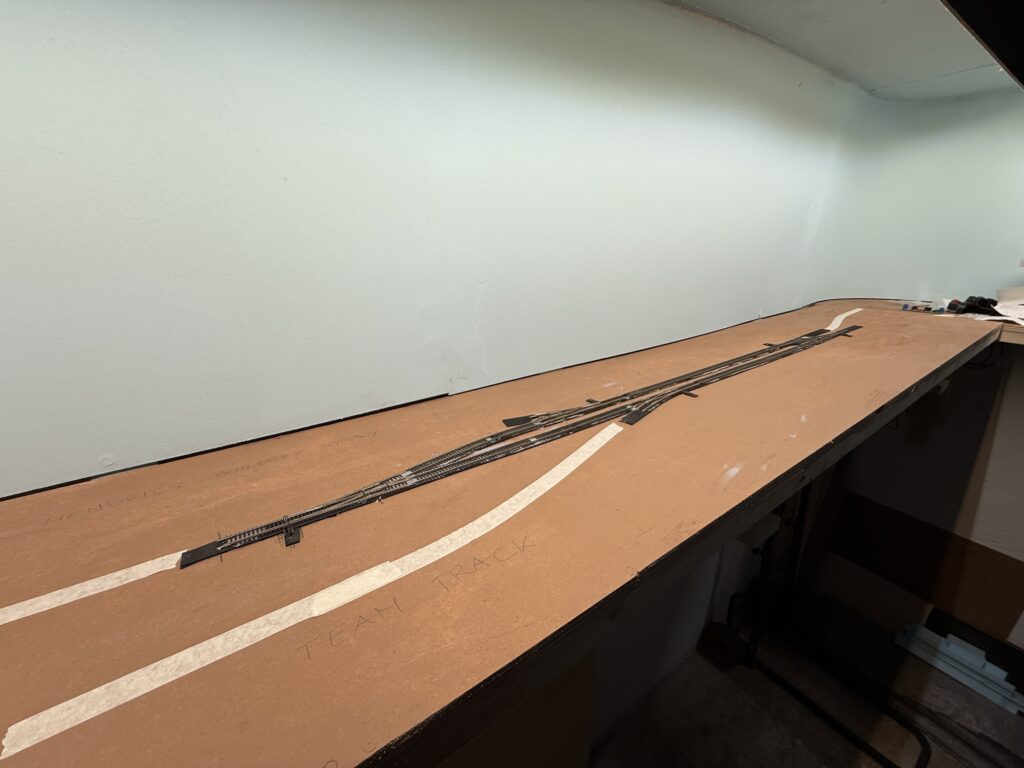

The main line and sidings are now in place. I’ll lay the spurs for Hendrick’s Supply Builders, Oroweat Bakery, and the Team Track next.

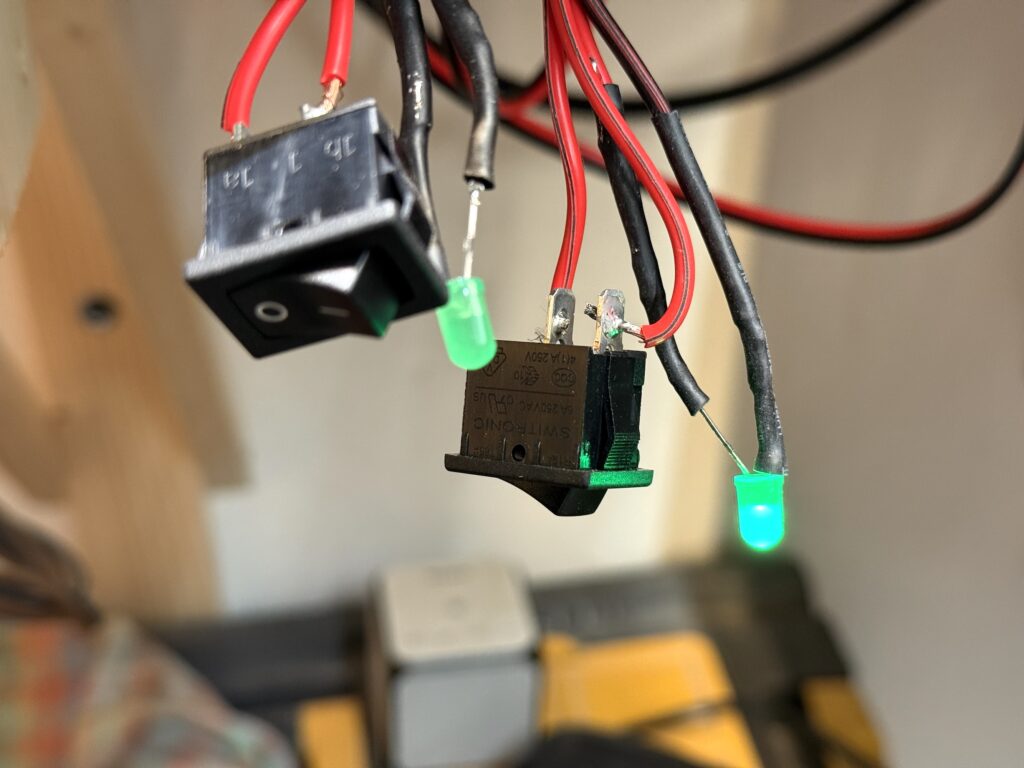

The team track will be wired through a DPDT switch, so it can also serve as a DCC programming track.

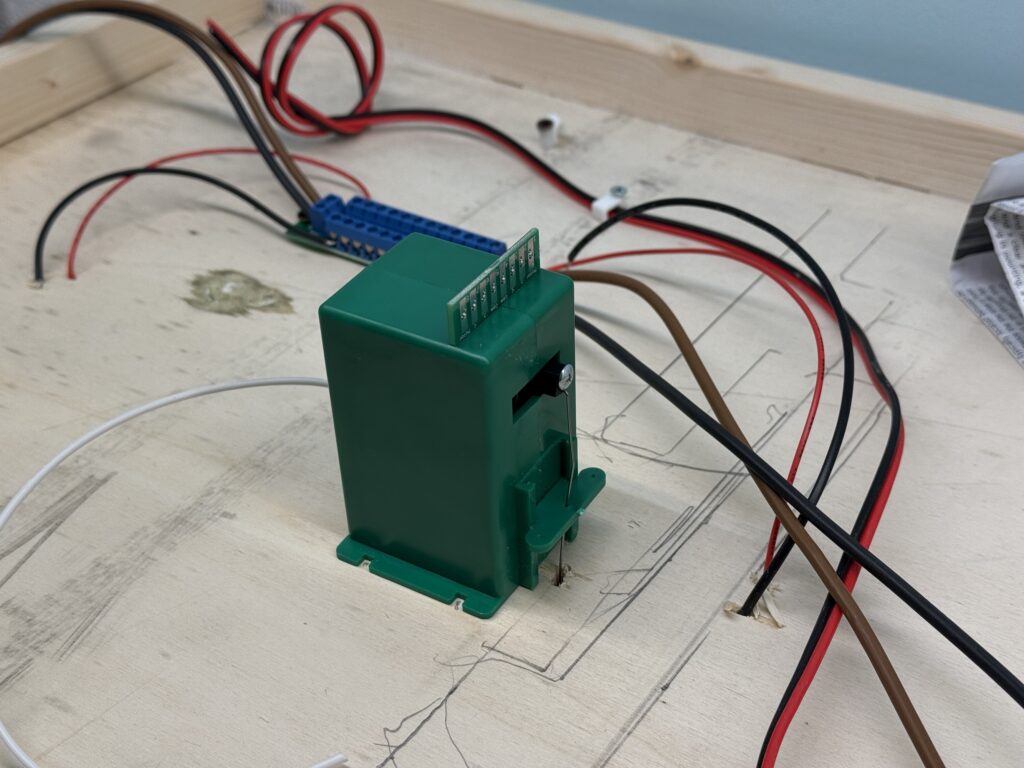

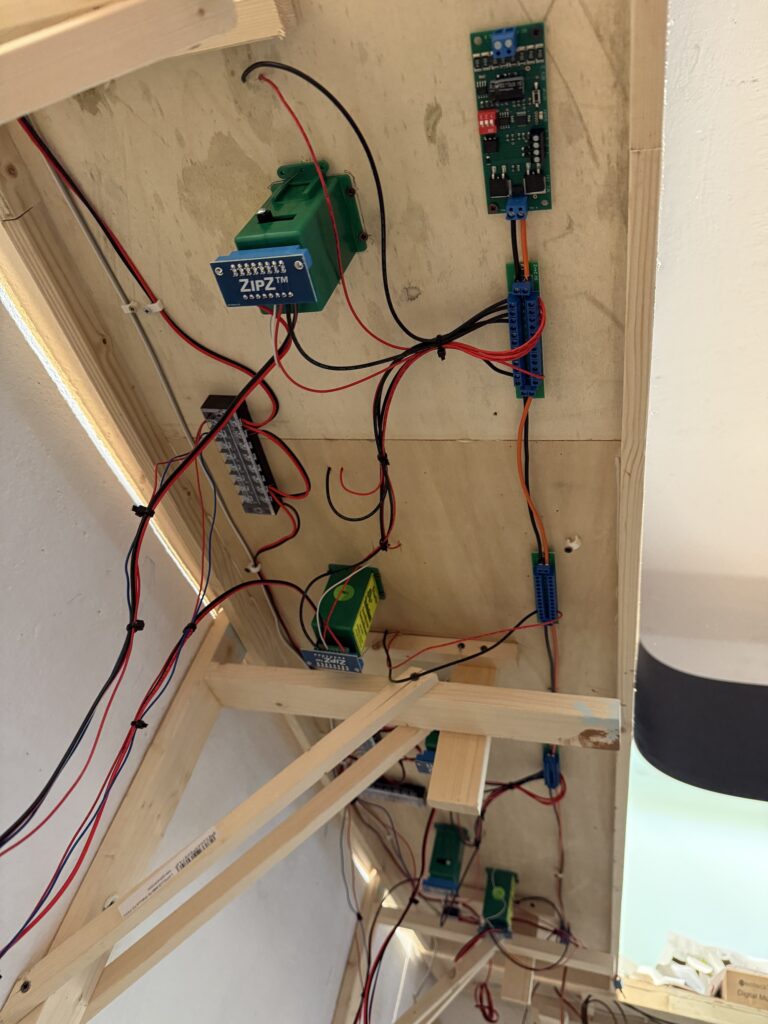

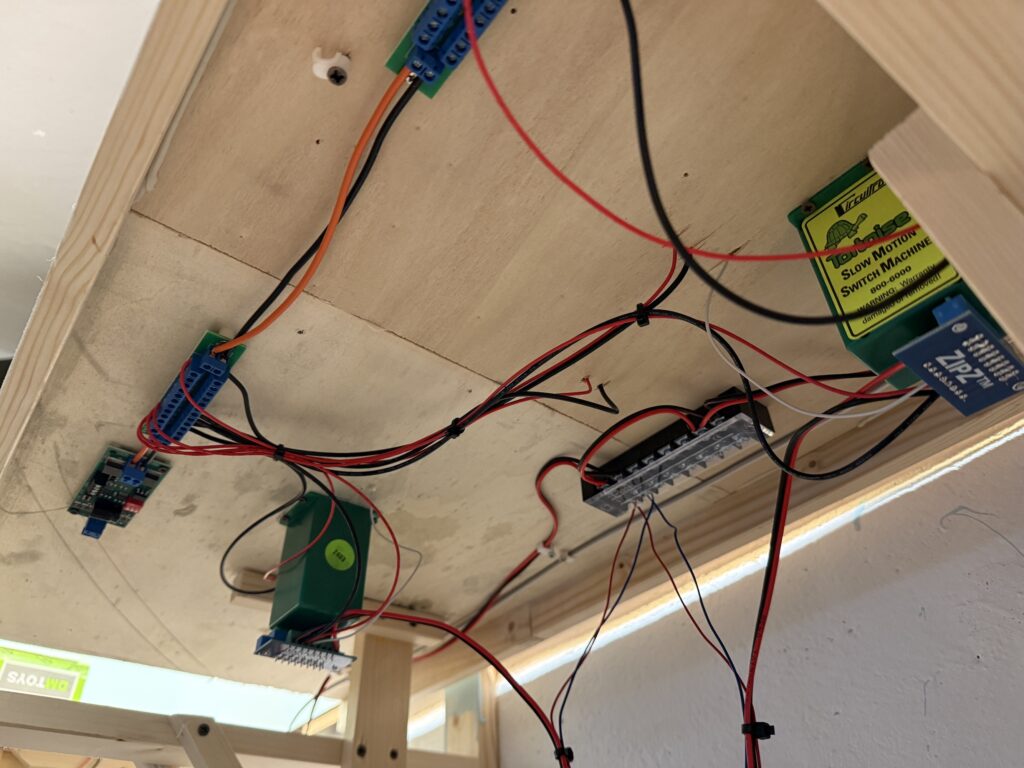

I used terminal strips and cable ties to organize the wiring. The wires hanging under the layout connect to the DPDT switches that control the Tortoise switch machines.

Then, these switches will be mounted on the fascia.

Wiring and laying tracks on a small switching layout requires planning, patience, and flexibility. Each step builds the foundation for smooth operations later on.

Using the right tools and techniques helps avoid frustration and saves time. As the layout grows, keeping things neat and modular makes future changes much easier.

With the basics in place, I’m excited to shift focus to detailing and fine-tuning operations.