Installing the valance

Using Faesite (Masonite) sheet, installing the valance is quick and easy.

I purchased some black Faesite (Masonite) sheets, had them cut to length, and used them to install the valance. A valance helps direct and diffuse light onto the layout while preventing glare from LED strips or other light sources.

Below is a short video showing the final result with LED lighting on my N scale layout.

Valance Installation

Just like with the backdrop, I bent the board to create a smooth, rounded corner.

Enhanced Visual Framing

The LED strips are hidden behind the valance. Installing the valance creates a more immersive and finished look by framing the scene and keeping the viewer’s focus on the trains and scenery. The valance helps conceal ceiling lights, room clutter, and other distractions outside the layout.

Depending on the height and depth of the valance, the valance may make the layout feel more enclosed or get in the way of taller operators. Also, installing a valance requires additional materials, cutting, mounting, and possibly bending for curved corners.

That said, a well-designed valance adds a professional touch, making the layout appear more polished and realistic.

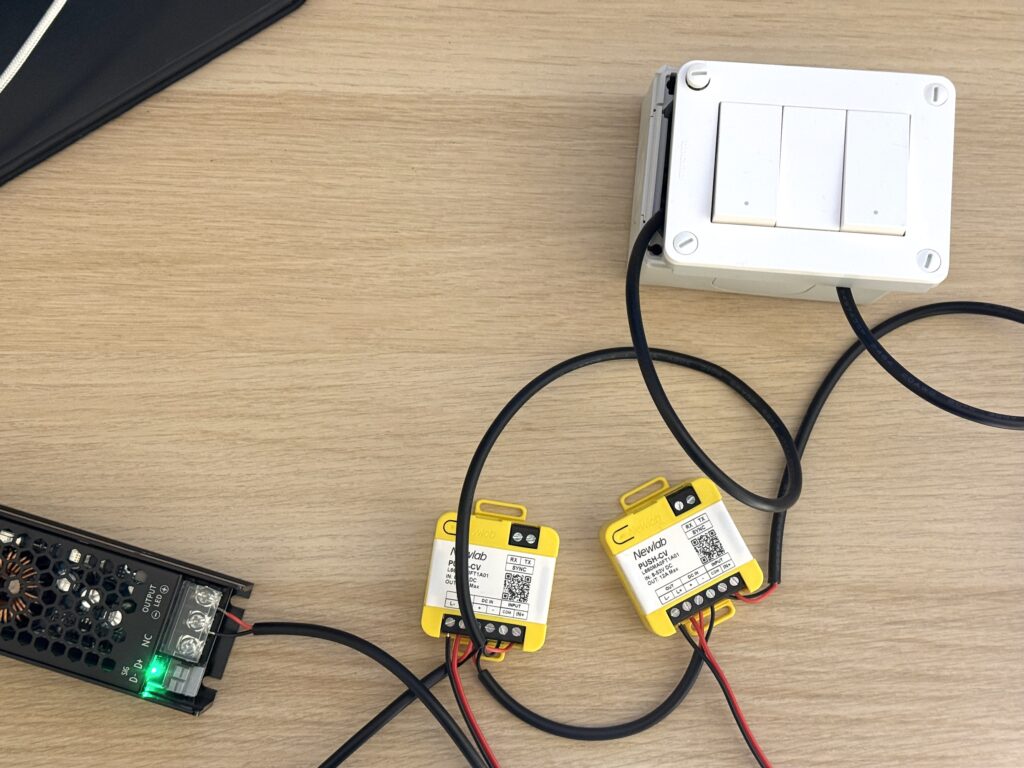

Lighting

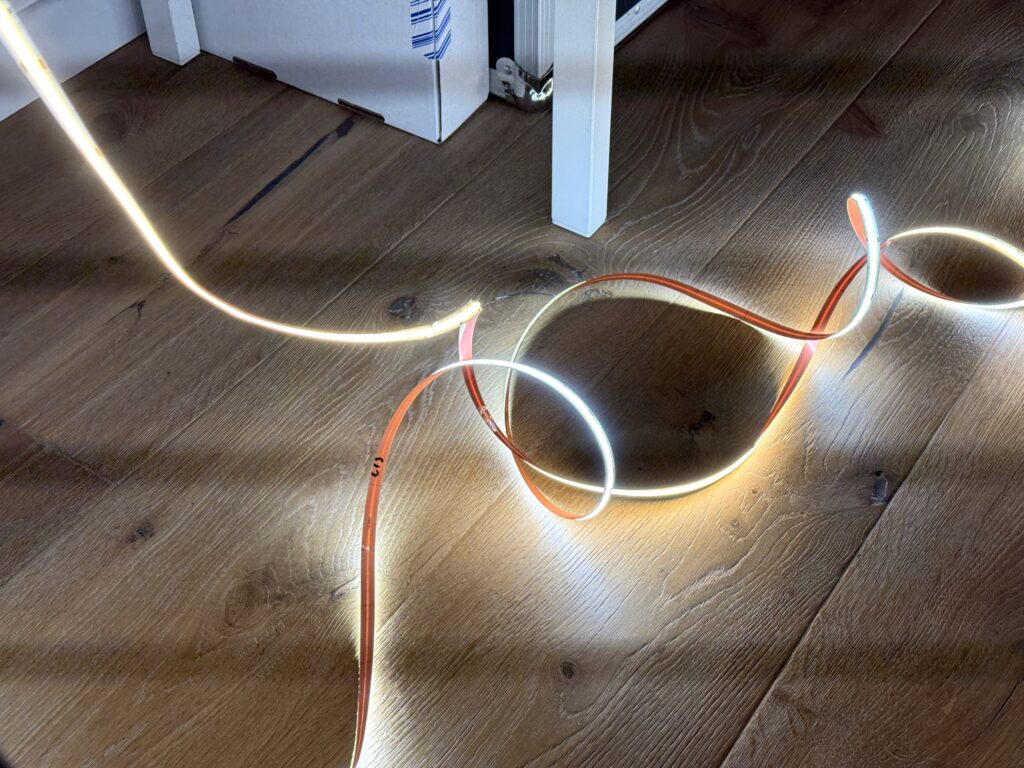

I use three LED strips of different colors: 2700K, 4000K and blue light. Each strip is wired to a dimmable power supplies and dimmers , allowing independent control. Remote push-buttons control the lights. I used Italian brand Bticino Matix Go push-buttons.

I usually use a combination of 4000K and 2700K for daylight, while the blue light is on for night operations. In the photo below, the blue appears more saturated than it does in person.

A well-planned valance and lighting setup transforms the look and feel of a model railroad. By combining different LED color temperatures, it’s possible to replicate natural lighting transitions, enhancing realism without drawing attention away from the trains.

Adjustable dimming and remote controls add convenience, allowing for seamless shifts between day and night scenes. Thoughtful lighting makes a huge difference in bringing the layout to life while keeping the focus on the trains and scenery.